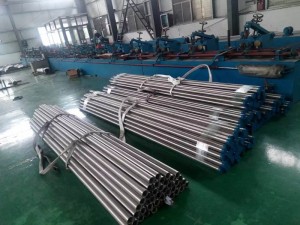

Kev tsim ntau yam precision ci raj

Precision yeeb nkab yog ib hom seamless steel yeeb nkab nrog high precision thiab siab brightness uas ua los ntawm txias txias los yog txias dov txheej txheem. Nws sab hauv thiab sab nraud txoj kab uas hla tuaj yeem ua kom raug rau hauv 0.2 hli. Nws tsis tsuas yog ua kom lub zog khoov thiab torsional, tab sis kuj muaj lub teeb yuag. Yog li ntawd, nws yog dav siv nyob rau hauv kev tsim cov precision mechanical qhov chaw thiab engineering lug. Nws kuj yog siv dav hauv kev tsim ntau yam riam phom, chim, plhaub, kabmob, thiab lwm yam.

Cov khoom siv feem ntau yog 10#, 20#, 35#, 45#, 20Cr, 40Cr, 20CrMo, 16Mn, 27SiMn, 304, 201, 310S, zoo carbon steel qauv.

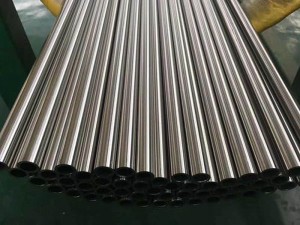

1. Me me sab nraud.

2. High precision thiab tuaj yeem siv rau kev tsim khoom me me.

3. Cold drawn khoom muaj siab precision thiab zoo nto zoo.

4. Qhov chaw hla ntawm cov yeeb nkab steel yog qhov nyuaj dua.

5.Cov yeeb nkab steel muaj kev ua tau zoo dua thiab cov hlau ntom ntom. Txoj kev tshuaj xyuas tuaj yeem siv cov dej xab npum los so cov pob qij txha ntawm lub qhov cub annealing kom pom seb puas muaj cua nkag; Ntawm lawv, qhov chaw uas muaj roj ntau tshaj yuav khiav tawm yog qhov chaw uas lub qhov cub annealing nkag thiab tawm hauv cov yeeb nkab. Lub nplhaib sealing nyob rau hauv qhov chaw no tshwj xeeb tshaj yog yooj yim hnav, yog li nws yuav tsum tau kuaj xyuas thiab hloov ntau zaus. Cov txheej txheem txheej txheem ntawm pretreatment ntawm precision steel yeeb nkab ua ntej txias dabtsi yog khoov yog muab tso rau pem hauv ntej; Cov teebmeem ntawm normalizing kub, tuav lub sij hawm thiab txias hom ntawm microstructure thiab mechanical zog ntawm cov yeeb nkab pub tau kawm thiab tshuaj xyuas; Cov txheej txheem normalizing ntawm precision steel yeeb nkab yog txiav txim siab: cov cua kub kub yog (890 ± 10) ℃, thiab tawg ua cua txias tom qab tuav rau 6min. Cov txheej txheem kev ua haujlwm zoo tuaj yeem tshem tawm cov qauv widmanstatten ntawm precision steel yeeb nkab, ua kom qhov sib txuam ntawm cov khoom muaj zog thiab lub zog tensile ntau tsim nyog, thiab txhim kho cov txiaj ntsig lub zog piv σ S / b σ ≤ 0.78, elongation 5 δ ≥ 30%, zoo heev txhim kho cov txias txoj kev ua tau zoo thiab tsis txhob txias bending cracking. Lub coefficient ntawm expansion yuav qhia tau nyob rau hauv ntim los yog ntev, feem ntau nyob rau hauv ntev. Qhov ntom ntom ntawm cov khoom yog qhov loj ntawm ib chav tsev ntim ntawm cov khoom, hauv kg / m3 lossis 1B / in3. Cov residual tensile stress feem ntau yog los ntawm residual tensile stress uas tsim los ntawm cov cuab yeej thaum vuam.

Tam sim no, annealing tom qab vuam txias yog dav siv nyob rau hauv engineering los tshem tawm cov residual kev nyuaj siab, thiab tom qab vuam txias yog ib tug tseem ceeb txheej txheem ntawm residual kev nyuaj siab. Txoj kev no tsis yog tsuas yog nkim lub zog, tab sis kuj yooj yim tsim cov vuam loj residual kev nyuaj siab. Kev kho cua sov tom qab vuam yog ib qho cuab yeej tshiab los tshem tawm cov kev ntxhov siab uas seem. Lub precision steel yeeb nkab yuav tsum tau preheated rau tom qab tshav kub kev kho mob kub ua ntej vuam, thiab cov vuam yuav tsum tsis tu ncua rhuab kom tswj tau qhov kub thiab txias thaum lub sij hawm vuam. Tom qab vuam, nws yuav tsum tau insulated nrog insulating paj rwb kom txias nws maj mam. quenching tuaj yeem ua rau lub zog thiab hardness ntawm cov yeeb nkab steel, tab sis txo nws cov plasticity. Cov tshuaj quenching feem ntau siv hauv quenching muaj xws li dej, roj, dej alkaline thiab ntsev. Tempering ntawm precision steel yeeb nkab reheats lub quenched precision steel yeeb nkab rau ib tug tej yam kub thiab txias nws los ntawm ib tug tej yam txoj kev, uas yog hu ua tempering. Lub hom phiaj yog txhawm rau tshem tawm cov kev ntxhov siab sab hauv uas tsim los ntawm quenching, txo hardness thiab brittleness, thiab tau txais cov khoom uas xav tau. Tempering tau muab faib ua qhov kub siab tempering, nruab nrab kub tempering thiab tsis kub tempering. Tempering feem ntau yog siv ua ke nrog quenching thiab normalizing. quenching thiab tempering kev kho mob txoj kev kho cua sov ntawm high kub tempering tom qab quenching yog hu ua quenching thiab tempering kev kho mob.