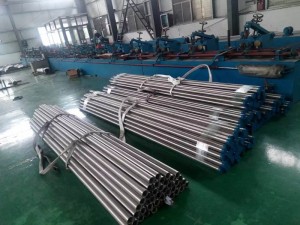

Tuam Tshoj 27SiMn hydraulic steel yeeb nkab chaw tsim tshuaj paus

27SiMn seamless steel yeeb nkab, piv txwv li 27 silicon manganese seamless steel yeeb nkab, yog ib qho ntawm cov ntaub ntawv ntawm seamless steel yeeb nkab, thiab cov ntsiab lus carbon yog nyob nruab nrab ntawm 0.24-0.32%. SIMN yog teev tseg vim hais tias cov ntsiab lus ntawm silicon manganese nyob rau hauv tsib lub ntsiab (carbon C, silicon Si, manganese Mn, phosphorus P, sulfur s) yog hais txog 1.10-1.40%. 27SiMn seamless yeeb nkab yog tsim rau cov fais fab nroj tsuag, boiler cog, tshuaj kev lag luam, tsheb thiab nkoj accessories, thiab lwm yam.

27SiMn, hydraulic strut yeeb nkab. Unified digital code: a10272

Txuj: GB / t17396-2018

Cov hlau no muaj cov khoom zoo dua li 30Mn2 steel, siab hardenability, tseem ceeb hardenability txoj kab uas hla ntawm 8 ~ 22mm hauv dej, zoo machinability, nruab nrab txias deformation plasticity thiab weldability; Tsis tas li ntawd, lub zog ntawm cov hlau tsis txo qis ntau thaum kho cua sov, tab sis nws muaj zog heev thiab hnav tsis kam, tshwj xeeb tshaj yog thaum dej quenching; Txawm li cas los xij, cov hlau no yog rhiab rau qhov chaw dawb, temper brittleness thiab overheating rhiab heev thaum kho cua sov.

Cov hlau no feem ntau yog siv rau hauv lub xeev quenched thiab tempered los tsim cov khoom kub stamping uas yuav tsum tau muaj siab toughness thiab hnav tsis kam; Nws tuaj yeem siv tau raws li qhov qub lossis kub dov khoom, xws li tsheb laij teb tus pin, thiab lwm yam.

Daim ntawv thov ntawm 27 SIMN seamless yeeb nkab thiab zoo tib yam steel yeeb nkab

27SiMn seamless steel yeeb nkab

27SiMn seamless steel yeeb nkab

1. Seamless steel yeeb nkab rau cov kua dej: GB / t8163-2018

2. Seamless steel yeeb nkab rau boiler: GB / t3087-2018

3. Kev kub siab seamless yeeb nkab rau boiler: GB / t5310-2018 (ST45.8 - hom III)

4. Kev kub siab seamless steel yeeb nkab rau cov khoom siv tshuaj chiv: GB / t6479-2018

5. Seamless steel yeeb nkab rau geological drilling: yb235-70

6. Seamless steel yeeb nkab rau roj drilling: yb528-65

7. Seamless steel yeeb nkab rau roj av tawg: GB / t9948-2018

8. Tshwj xeeb seamless yeeb nkab rau roj av laum dab tshos: yb691-70

9. Seamless steel yeeb nkab rau tsheb qag ncej: GB / t3088-2018

10. Seamless steel yeeb nkab rau nkoj: GB / t5312-2018

11. Cold drawn txias dov precision seamless steel yeeb nkab: GB / t3639-2018

12. Seamless steel yeeb nkab rau hydraulic prop: GB / t17396-2018

Mechanical zog ntawm 27SiMn seamless steel yeeb nkab

Tensile zog σb (MPa): ≥980

yield zog σ s (MPa): ≥835

Elongation δ 5 / (%): ≥12

Txo thaj tsam ψ/(%): ≥40

Impact absorption zog (tus nqi cuam tshuam) (aku2 / J): ≥ 39

Tag nrho cov kav dej seamless steel yuav tsum raug kuaj rau cov khoom siv kho tshuab. Cov kev sim ntawm cov cuab yeej siv tshuab feem ntau yog muab faib ua ob pawg: tensile test thiab hardness test.

Tensile xeem yog ua kom seamless steel yeeb nkab rau hauv cov qauv, rub tus qauv kom tawg ntawm lub tensile kuaj tshuab, thiab tom qab ntawd ntsuas ib lossis ob peb lub zog. Feem ntau, tsuas yog lub zog tensile, lub zog tawm los, elongation tom qab tawg thiab txo ntawm cheeb tsam raug ntsuas.

Kev sim hardness yog maj mam nias ib qho nyuaj indenter rau hauv cov qauv saum npoo raws li cov xwm txheej tau teev tseg, thiab tom qab ntawd kuaj qhov tob lossis qhov loj me, txhawm rau txiav txim siab qhov hardness ntawm cov khoom.

Zoo machinability, nruab nrab txias deformation plasticity thiab weldability; Tsis tas li ntawd, lub zog ntawm cov hlau tsis txo qis ntau thaum kho cua sov, tab sis nws muaj zog heev thiab hnav tsis kam, tshwj xeeb tshaj yog thaum dej quenching; Txawm li cas los xij, cov hlau no yog rhiab rau qhov chaw dawb, temper brittleness thiab overheating rhiab heev thaum kho cua sov.

Kev ceev faj rau kev soj ntsuam siab ntawm seamless steel yeeb nkab

Kev ceev faj rau kev tshuaj xyuas qhov siab ntawm seamless steel yeeb nkab feem ntau suav nrog cov ntsiab lus hauv qab no:

1. Qhov tob thiab qhov tob ntawm decarburization.

2. Ntev thiab qhov tob ntawm qhov deg dov tsis xws luag, shrinkage kab noj hniav, hauv nruab nrab segregation ntawm carbon thiab sulfur.

3. Kev faib tawm ntawm ferrite thiab pearlite hauv seamless steel yeeb nkab.

4. Lwm yam microstructure defects, raws li zoo raws li grain loj, seamless yeeb nkab nto roughness thiab inclusion ntsiab lus.