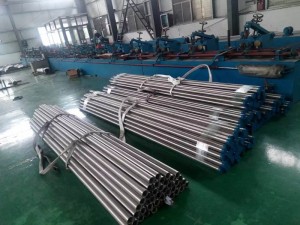

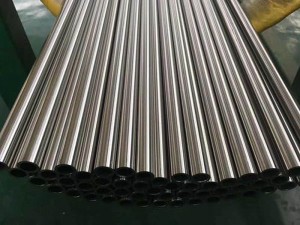

Kev muag khoom ntawm precision ci raj

Cold rolled seamless yeeb nkab (GB3639-2000) yog ib qho txias rub los yog txias dov precision seamless steel yeeb nkab nrog siab qhov tseeb thiab zoo nto tiav rau cov khoom siv tshuab thiab cov khoom siv hydraulic. Ntxiv rau cov yeeb nkab dav dav, qis thiab nruab nrab siab boiler steel yeeb nkab, siab siab boiler steel yeeb nkab, alloy steel yeeb nkab, stainless hlau yeeb nkab, roj av cracking yeeb nkab thiab lwm yam steel kav, txias dov (kos) seamless yeeb nkab kuj muaj xws li carbon nyias-walled. steel yeeb nkab, alloy nyias-walled steel yeeb nkab, stainless nyias-walled steel yeeb nkab thiab tshwj xeeb-zoo li tus steel yeeb nkab. Sab nraud txoj kab uas hla ntawm kub dov seamless yeeb nkab feem ntau ntau dua 32 hli thiab phab ntsa thickness yog 2.5-75 hli. Txoj kab uas hla ntawm txias-dov seamless steel yeeb nkab tuaj yeem ncav cuag 6 hli thiab phab ntsa tuab tuaj yeem ncav cuag 0.25 hli. Sab nraud txoj kab uas hla ntawm nyias-walled yeeb nkab tuaj yeem ncav cuag 5 hli thiab phab ntsa thickness tsawg dua 0.25 hli. Txias dov muaj qhov tseeb qhov tseeb dua li qhov kub dov.

1.Cold dov steel tso cai rau hauv zos buckling ntawm seem, uas tuaj yeem siv tag nrho cov kabmob muaj peev xwm ntawm tus tswv cuab tom qab buckling; Qhov kub-kuav los tiag seem steel tsis tso cai rau hauv zos buckling.

2.Qhov ua rau muaj kev ntxhov siab nyob rau hauv kub dov seem steel thiab txias dov seem steel yog txawv, yog li qhov kev faib tawm ntawm seem kuj txawv heev. Qhov seem ntawm kev ntxhov siab nyob rau hauv seem ntawm qhov txias-tsim nyias-walled seem steel yog dabtsi yog khoov hom, thaum seem kev ntxhov siab faib rau hauv seem ntawm kub dov seem steel los yog welded seem steel yog nyias-film hom.

3. Qhov dawb torsion nruj ntawm kub-kuav los tiag seem steel yog siab dua li ntawm txias-kuav los tiag seem steel, yog li qhov torsion tsis kam ntawm kub-kuav los tiag seem hlau yog zoo dua li ntawm txias-kuav los tiag seem hlau.

Txias dov yog hais txog kev ua cov hlau phaj lossis sawb rau hauv ntau hom hlau ntawm chav tsev kub los ntawm kev kos duab txias, txias khoov, kos duab txias thiab lwm yam ua haujlwm txias.

Qhov zoo:kev sib sau ceev ceev, cov zis siab, tsis muaj kev puas tsuaj rau cov txheej txheem, thiab tuaj yeem ua rau ntau hom ntawv hlais kom tau raws li cov kev xav tau ntawm kev pabcuam; Txias dov tuaj yeem tsim cov yas deformation zoo ntawm cov hlau, txhawm rau txhim kho cov txiaj ntsig ntawm cov hlau.

Qhov tsis zoo:1. Txawm hais tias tsis muaj cov yas kub compression nyob rau hauv txoj kev tsim, tseem muaj kev ntxhov siab nyob rau hauv seem, uas yuav inevitably cuam tshuam rau tag nrho thiab hauv zos buckling yam ntxwv ntawm steel; 2. Cov style ntawm txias dov seem steel yog feem ntau qhib seem, kom cov dawb torsional nruj ntawm seem yog tsawg. Torsion yooj yim tshwm sim nyob rau hauv khoov, khoov thiab torsional buckling yog ib qho yooj yim tshwm sim nyob rau hauv compression, thiab torsional kev ua tau zoo yog tsis zoo; 3. Lub phab ntsa thickness ntawm txias-dov ua hlau yog me me, thiab tsis muaj thickening ntawm lub ces kaum ntawm phaj kev twb kev txuas, yog li lub peev xwm los dais lub zos concentrated load yog tsis muaj zog.

Piv nrog rau cov yeeb nkab txias-dov seamless, cov yeeb nkab kub-dov seamless yog dov hauv qab qhov kub ntawm recrystallization, thiab cov yeeb nkab kub-dov seamless yog dov saum toj no lub recrystallization kub.

Qhov zoo:Nws tuaj yeem rhuav tshem cov qauv casting ntawm ingot, kho cov nplej ntawm cov hlau thiab tshem tawm qhov tsis xws luag ntawm microstructure, thiaj li ua kom cov hlau compact thiab txhim kho cov khoom siv kho tshuab. Qhov kev txhim kho no feem ntau yog tshwm sim hauv cov kev taw qhia dov, kom cov hlau tsis muaj isotropic rau qee yam; npuas, tawg thiab looseness tsim thaum lub sij hawm pouring kuj yuav welded nyob rau hauv qhov kev txiav txim ntawm kub thiab siab.

Qhov tsis zoo:1. Tom qab kub dov, cov non-metallic inclusions (tsuas yog sulfide, oxide thiab silicate) nyob rau hauv cov hlau yog nias rau hauv nyias nyias, uas ua rau delamination (interlayer) tshwm sim. 2. Delamination zoo heev deteriorates lub tensile zog ntawm steel raws thickness kev taw qhia, thiab interlayer kua muag yuav tshwm sim thaum lub weld shrinks. Lub cheeb tsam induced los ntawm weld shrinkage feem ntau mus txog ob peb lub sij hawm ntawm yield point strain, uas yog loj npaum li cas los ntawm load; 2. Kev ntxhov siab uas tshwm sim los ntawm qhov tsis sib xws. Residual stress yog qhov kev ntxhov siab hauv tus kheej sib npaug yam tsis muaj kev quab yuam sab nraud. Kub dov ntu ntawm ntau ntu muaj qhov kev ntxhov siab zoo li no. Feem ntau, qhov loj dua qhov loj ntawm seem steel, qhov ntau dua qhov kev ntxhov siab seem. Txawm hais tias qhov seem ntawm kev ntxhov siab yog qhov sib npaug ntawm tus kheej, nws tseem muaj qee yam cuam tshuam rau kev ua haujlwm ntawm cov tswv cuab steel nyob rau sab nraud quab yuam. Piv txwv li, nws yuav muaj kev cuam tshuam tsis zoo rau deformation, stability thiab qaug zog. 3. Lub thickness thiab sab dav ntawm cov khoom kub dov steel tsis yooj yim los tswj. Peb paub txog thermal expansion thiab txias contraction. Txawm hais tias qhov ntev thiab tuab ua tau raws li tus qauv thaum pib ntawm kev kub dov, yuav muaj qhov txawv tsis zoo tom qab txias. Qhov dav ntawm ntug dav ntawm qhov sib txawv tsis zoo no yog, qhov tuab tuab yog, qhov pom tseeb dua nws yog. Yog li ntawd, rau cov hlau loj, sab dav, tuab, ntev, lub kaum sab xis thiab ntug kab ntawm cov hlau tsis tuaj yeem yuav tsum tau ua kom raug ntau dhau.

(1) General qauv Seamless yeeb nkab rau cov neeg kho tshuab qauv (GB / t8162-87) (2) seamless yeeb nkab rau qis thiab nruab nrab siab boiler (GB / t3087-1999) (3) seamless yeeb nkab rau siab boiler st45.8/111 ( GB / t5310-85) (4) seamless yeeb nkab rau cov kua kis tau tus mob (GB / t8163-1999) (5) txias rub los yog txias dov precision seamless yeeb nkab (GB / t3639-83) (6) steel yeeb nkab rau geological drilling (yb235- 70) (7) roj av drilling steel yeeb nkab (yb528-65) (8) ) Seamless yeeb nkab rau precision puab txoj kab uas hla ntawm hydraulic lub tog raj kheej chim (GB8713-88) (9) seamless yeeb nkab rau tshuaj chiv (gb6479-86) (10) marine yeeb nkab (gb5312-85) (11) roj av cracking yeeb nkab (gb9948-88) (12) ntau yam alloy kav 16Mn 27SiMn 15CrMo, 35CrMo 12CrMoV 20g 40Cr